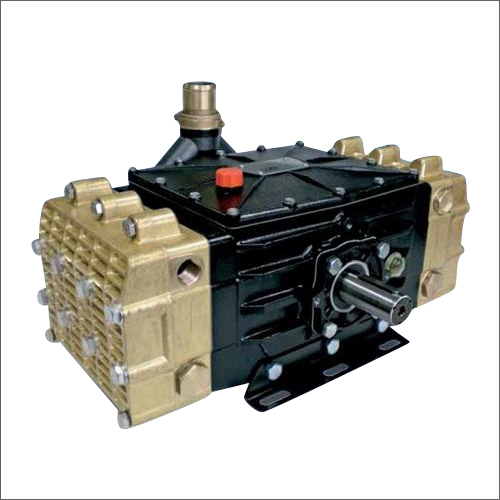

Ultra High Pressure Pump

Price 65399.0 INR/ Number

MOQ : 1 Number

Ultra High Pressure Pump Specification

- Frequency

- 50 Hz Hertz (HZ)

- Features

- Durable Compact

- Discharge Pressure

- Ultra High

- Flow Rate

- Variable

- Voltage

- 220-240 V Volt (v)

- Head Size

- Standard

- Mounting Type

- Horizontal

- Theory

- Positive Displacement Principle

- Inlet/Outlet

- Multiple Connections

- Control System

- Manual

- Caliber

- High

- Working Temperature

- 0C to 60C Celsius (oC)

- Max Suction

- 10 meters

- Material

- Brass and Steel

- Size

- Standard

- Structure

- Other

- Power

- 5 HP

- Standard

- ISO Certified

- Product Type

- Ultra High Pressure Pump

- Fuel Type

- Electric

- Pressure

- 500 bar

- Color

- Black And Golden

- Usage

- Other

- Application

- Other

- Suction Type

- Positive Displacement

- Seals Type

- High-Pressure Seals

- Priming

- Non-self Priming

- Pump Type

- Reciprocating Pump

Ultra High Pressure Pump Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 10 Per Week

- Delivery Time

- 7 Days

About Ultra High Pressure Pump

Ultra High-Pressure Pump is similar to a fuel pump in design, but the latter is more sophisticated. Its function is to pressurize fuel before it is sent to the fuel rail after entering from the fuel tank. The GDI system contains a fuel pressure sensor. Apart from this, the Ultra High-Pressure Pump enables a very broad range of applications. It generates the flow required for the creation of pressure, which is dependent on the system's fluid flow resistance.

Product Details :

Product Details :

|

Minimum Order Quantity |

1 Set |

|

Model Name/Number |

CC 38/17S |

|

Brand |

Udor |

|

Max Flow Rate |

38LPM@100Bar |

|

Power Source |

Petrol |

Robust Construction and Versatility

Made with premium brass and steel, this pump stands out for its strength and resilience in demanding industrial workflows. Its compact, horizontal design and multiple connection options allow for easy integration into diverse systems. The black and golden color scheme highlights its modern feel and aligns with industrial standards.

Precision Control and High Performance

Equipped with a manual control system and positive displacement suction, the pump delivers precise and stable flow at variable rates. It achieves ultra-high discharge pressure up to 500 bar and supports a wide range of voltages (220-240V), ensuring compatibility with most industrial setups. The standard size and head enable seamless installation.

Certified Safety and Reliability

Each pump complies with ISO certification, guaranteeing stringent quality and safety standards. High-pressure seals provide reliable leak protection and support continuous operation between 0C and 60C. The electric fuel type and 5 HP power ensure consistent performance, ideal for exporters, manufacturers, and suppliers.

FAQ's of Ultra High Pressure Pump:

Q: How does the positive displacement principle benefit this pump's operation?

A: The positive displacement principle enables the pump to deliver a consistent and fixed flow rate, even when pressure conditions change. This results in stable and reliable performance, critical for high-pressure industrial applications requiring precise fluid handling.Q: What are the recommended usage scenarios for this ultra high pressure pump?

A: This pump is specifically designed for heavy-duty industrial environments where ultra-high discharge pressure and variable flow rates are needed. Its robust construction and versatile mounting options make it well-suited for manufacturing plants, workshops, and export operations.Q: When should the manual control system be adjusted during operation?

A: Manual control should be adjusted when you need to change the flow rate or adapt to varying process requirements. Regular adjustments also help optimize efficiency and maintain safety, especially when operating under fluctuating demands or pressures.Q: Where can this pump be installed given its mounting type and connection options?

A: With its horizontal mounting design and multiple inlet/outlet connection points, the pump can be installed in industrial piping systems, machinery lines, or customized setups that require flexible integration. Its standard size allows for easy replacement or retrofitting in existing facilities.Q: What is the process for starting and priming this non-self priming pump?

A: As a non-self priming pump, it requires manual priming before use. The process involves filling the pump and suction line with liquid prior to operation to ensure efficient start-up and prevent dry run damage to seals and internal components.Q: How does the pump's high-pressure seal type enhance reliability?

A: High-pressure seals are engineered to withstand extreme pressure levels, providing leak-proof operation and extending the lifespan of the pump. This minimizes maintenance needs and ensures continuous, safe operation even in harsh working conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in High Pressure Pump Category

6 Plunger Pump

Price 365099.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel

Frequency : 50 Hertz (HZ)

Voltage : 220 Volt (v)

Product Type : 6 Plunger Pump

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS